4 IT Sourcing and Procurement Best Practices

Park Place Hardware Maintenance

Taking care of your data center requires 24/7 supervision. From initial procurement and purchasing to consistent maintenance, repairs, and support, the information technology procurement process takes a great amount of attention.

Jump-to Section

Top Challenges in IT Procurement

Chip Shortages Causing Lead Time Delays

Logistics and Staffing Barriers

High Demand and Fluctuating Prices

4 IT Hardware Procurement Best Practices

1. Identify Requirements for Business

2. Find Suppliers with Globally Distributed Inventory

When it’s time to invest, or re-invest, in your data center infrastructure, you need to be sure that you:

- Know your current assets along with warranties, contracts, and EOL/EOSL dates

- Clearly define your parameters

- Learn the options of potential vendors

- Vet vendors to maintain ongoing relationships

What Is IT Procurement?

IT procurement is the exercise of sourcing and purchasing information technology hardware and components from a hardware or software vendor. Depending on the scale of your IT needs, the IT procurement process may involve a Request for Proposal (RFP) for which vendors submit competitive bids.

After accruing a pool of bids and quotes, IT procurement professionals must evaluate pricing, lead time, and vendor reputation before making a purchase decision. In hyper-competitive markets, IT equipment lead times have grown incredibly long, causing procurement teams to place a premium on suppliers that can deliver IT hardware within short periods of time.

Top Challenges in IT Procurement

In any given year, poor communication and questionable infrastructure prove themselves to be major challenges for IT purchases. You must first understand what IT problems exist in your data center before moving on to challenges that are manifesting themselves in the current market.

Chip Shortages Causing Lead Time Delays

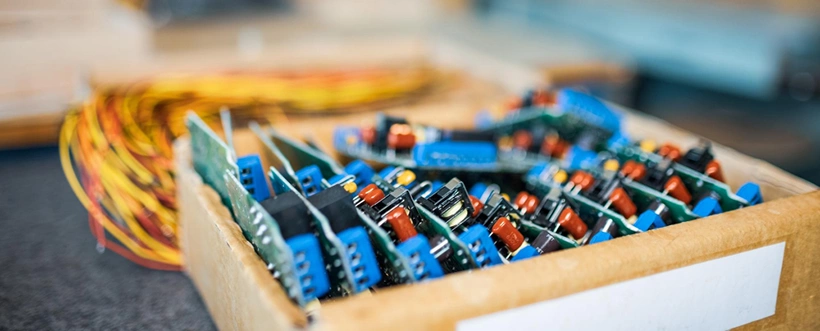

Due to supply chain issues at every level, chip shortages have become a problem and are causing lead time delays. The pandemic, staffing issues, raw material delays, and economic uncertainty are combining to significantly delay chip production.

Within the past year, it has been reported by supply chain publications that lead times are the highest since data started being kept in 1987. Lead time for electronic supplies can stretch to more than a year, according to the Institute for Supply Management. The problem is truly global. APAC companies are reporting 20 month-lead times for chips and circuit boards. Industry publications report that leading chip tool makers such as Applied Materials, KLA, Lam Research, and ASML are warning clients that they may have to wait 18 months for specific chips.

Greater Logistics and Staffing Barriers

Once products are manufactured, the logistics of getting them from the vendor to the purchaser remain. Logistics are currently struggling to reliably deliver. One option being reviewed among top hardware distributors is using global distribution centers, closer to customers. Another option is improving and increasing the number of on-site spares kits.

Hiring vendors that can work across multiple OEM products is a good answer to the challenge, versus a company that works on only one OEM line.

Fluctuating Prices Due to High Demand

Domestic and international inflation continues, and nobody can know when it will abate. The cost of packaging materials, for example, has jumped up several times over the past year. Companies are willing to pay the higher cost of packaging materials because these companies are eager to secure the needed materials so they can ship their products. It is often the vendors who are absorbing the increased costs, although some will pass these costs on to the end-user through higher prices or other fees.

4 Best Practices for Your IT Hardware Procurement Process

You need to understand your IT infrastructure before you can start making plans for further asset procurement. In IT sourcing best practices, you need to ascertain what assets you have and determine if you should have a health check run on any of them.

Do you have a spreadsheet or subscribe to a program that keeps track of warranties, contracts, and EOL/EOSL dates? Perhaps you rely on the help of an automated IT asset discovery tool to account for your full estate. Regardless of your current process, there are four practices that can help.

1. Identify Requirements for Business

Once you have taken inventory of your current and desired IT infrastructure, you can then be exacting in your purchases. This is where you need to be as specific as possible and acknowledge the difference between needs and wants.

In addition to new OEM equipment, your business could consider preowned network gear, servers, or storage hardware if it would work in your data center. If you don’t know specifically what you need, you may overspend or underspend, or simply misspend, purchasing the wrong gear.

Preowned Hardware also presents more options. You are not constrained by the high cost of some devices. You also have more flexibility in that you can buy previous generation hardware versus being stuck with only the “latest and greatest” option. Lastly, preowned hardware gives you the option to design by availability. You can work with your vendor to buy the hardware that is available within days and not years. This also allows you to buy similar or the same to what you currently have deployed.

2. Find Suppliers with Globally Distributed Inventory

In reviewing your supplier strategy and searching for suppliers, your procurement teams need to vet your potential suppliers well, with the goal of establishing good relationships so that you don’t have to perform the vetting process every time you need a hardware refresh or upgrade. You should not limit yourself to the same OEMs you’ve always used. Broaden your search to Value-Added-Resellers (VARs) when determining suppliers and contracts, in order to maximize your spend. Find suppliers with global distribution centers.

3. Look Beyond the OEM for Discounts

Better service and better prices are found in VARs. These companies often stock inventory so logistics are more easily handled and lead times are minimized. Their sales agents are quick to respond and they want what is best for the consumer, so are unlikely to push for a complete upgrade simply because an OEM is pushing a new product line. With resellers, you receive attention and service from consultative sales agents who listen to what you say.

4. Prepare Backup Vendors

Your network uptime is dependent on the integrity of your physical data center infrastructure. If you can’t procure the parts your IT team needs from your main vendor, it can be an arduous process to quickly source the equipment from a supplier that is not already on your preferred supplier list (PSL). Having at least one backup vendor available in the event of component availability will help improve the odds that you secure the required equipment on time.

Consolidate Your IT Continuity Vendor Relationships Today

As an IT leader, you understand that managing relationships with multiple vendors can quickly become overwhelming. Consolidating vendors to one reliable source, so you can minimize your time interfacing with partners and, instead, focus on achieving core outcomes, helps reduce stress levels and improves performance.

Park Place Technologies is a global data center and networking optimization firm offering IT hardware sales as well as third party data center hardware maintenance to extend the life of your IT assets. With a robust team of advanced on-the-ground engineers, we leverage our relationships with vendors around the world, increasing performance and Uptime.

Contact us today to learn how we can support your IT needs.